Sustainability

Why?

From rising sea levels to natural resource depletion, everywhere we look there seems to be an environmental challenge.

Green Thinking by BROEN

At BROEN we are on a journey, together with our customers, our suppliers, our employees and our owners at Aalberts. We know that every little bit counts, that every action makes a difference, and that change starts with us.

4 UN goals lead the way

The four Sustainable Development Goals have been chosen because it is in relation to these goals that we can make the biggest difference. As a leading manufacturer of valves, actuators and comprehensive control solutions, our products play a critical role in many systems around the world, including building installations, industrial processes, energy sector, offshore and marine.

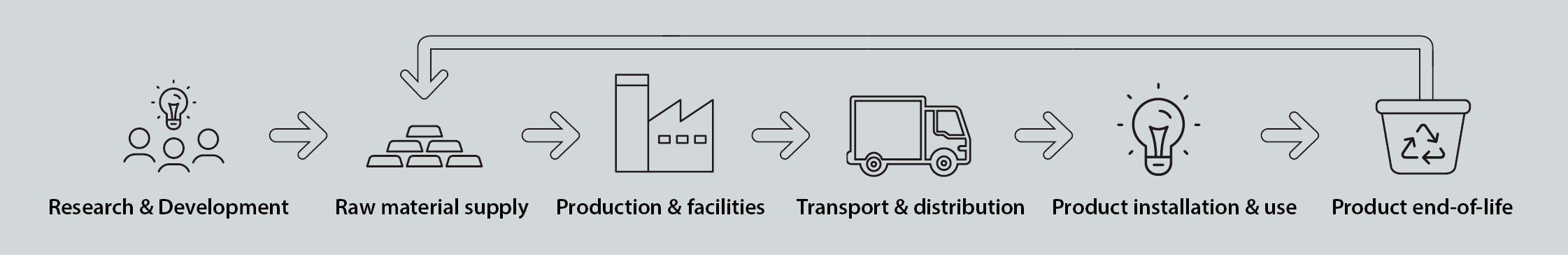

As a supplier to these industries, we can’t help but take our share of the responsibility for making them as sustainable as possible, as quickly as possible. As well as developing more energy-efficient solutions that last longer and require less maintenance, we are also documenting the climate impact of our products, for example through Life Cycle Assessments and Environmental Product Declarations. In this way, we are helping to meet the climate demands of industry now and in the future.

6. Clean water and sanitation

Ensure availability and sustainable management of water and sanitation for all.

- The BROEN FULL FLOW products made of stainless-steel material go beyond what is legally required in many countries.

- The BROEN FULL FLOW ball valves are made “cavity free” so that the valve is continuously flushed through to avoid stagnant water in the valve and thus growth of bacteria.

7. Affordable and clean energy

Ensure access to affordable, reliable, sustainable and modern energy for all.

- BROEN cooperate with several interest groups like Danish District Heating Association and State of Green.

- Products from BROEN make buildings more energy efficient.

- BROEN FULL FLOW with an energy-optimized flow design that will ensure a very low internal flow resistance.

8. Decent work and economic growth

Promote sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all.

- BROEN nurture personal growth in a safe and healthy working environment.

- BROEN meet employees with flexibility, trust and respect.

- BROEN support education plans on all organizational levels.

- BROEN embrace diversity among our staff, as this will provide the best input to our business.

- BROEN suppliers must accommodate certain requirements stated in our code of conduct in terms of how they handle health and safety of their employees.

- BROEN want to design new innovative products that are less resource-demanding in both production and operation.

12. Responsible consumption and production growth

Ensure sustainable consumption and production patterns.

- BROEN have a special focus on avoiding material waste and consequently all metals are recycled. Going forward, we also want to reduce the consumption of plastic and packaging.

- When BROEN develop new products, we optimize on e.g., the environmental profile of the material, energy consumption and how we can recycle the product.

- BROEN follow the principles in the UN Global Compact in terms of human rights, sustainability, anti-corruption etc. This also applies to our suppliers.

- BROEN are subject to a ”Code of Conduct” from our owner Aalberts N.V. which also requires responsible and sustainable business conduct.

|

Did you know?

The Sustainable Development Goals are 17 concrete goals that commit all 193 UN member states to end poverty and hunger, reduce inequalities, ensure quality education and better health for all, decent jobs and more sustainable economic growth.

First mover in our industry

Our target is to reduce product weight by 25% and CO2 emissions by 5% - focusing on:

- Always improve vital product parameters

- Reduction of product weight

- Reduce the number of components and process steps

- Reduce product variance, by use of modularity

- Selection of processes with low energy consumption and waste

- Reduce the number of mixed material types and allow

- disassembly when mixing materials types

ISO 14001:

ISO 14001 is an internationally agreed standard that forms the basis for environmental management applicable to any type of organisation in any industry. The standard sets out the criteria for creating an environmental management system based on the company, its processes and activities with allocation of responsibilities and competencies as well as day-to-day environmental tasks.

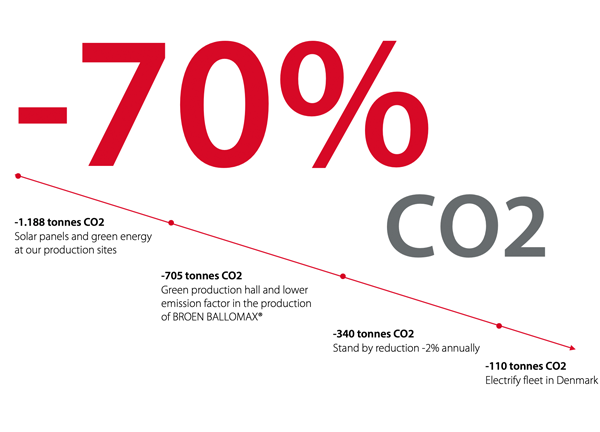

CO2 reduction by 2026

When we allow ourselves to say that we are first movers, it’s about much more than developing products that contribute to reducing CO2 emissions. BROEN have already taken the first steps towards becoming a CO2-neutral company back in 2018 - and we are working hard to reach the goals set for 2026. With one foot halfway into the future, Aalberts as owners of BROEN Valve Technologies are ready to support the initiatives we are launching - and for that we are grateful.

Scope 1, 2 and 3 is a way of categorizing the different kinds of carbon emissions a company creates in its own operations, and in its wider value chain.

Scope 1 emissions: This one covers the Green House Gas (GHG) emissions that a company makes directly - for example, while running its boilers and vehicles.

Scope 2 emissions: These are the emissions it makes indirectly – like when the electricity or energy it buys for heating and cooling buildings is being produced on its behalf.

Scope 3 emissions: Now here’s where it gets tricky. In this category go all the emissions associated, not with the company itself, but that the organization is indirectly responsible for, up and down its value chain. For example, from buying products from its suppliers, and from its products when customers use them. Emissions-wise, Scope 3 is nearly always the big one.

How?Net zero carbon roadmap Scope 1 & 2 Scope 3 |

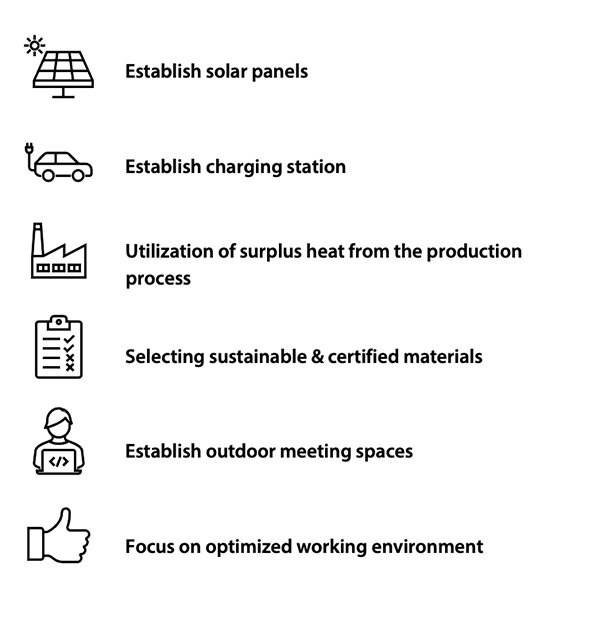

Sustainable construction in Assens

We aim for a DGBN-gold certification.

This means that we have considered environmental, economic, social, technical, process and area in the construction process, resulting in these six focus areas:

Solar panels: 240 modules are set up – approx. 468 m2.Expected production approx. 93,000 kWh/year.Savings of approx. 13 tonnes of CO2.

Chargers for electric cars:12 CLEVER charging units have been installed. When company electric cars are 100% phased in over the next 3 years, we expect to save approx. 45,000 litres of fuel per year – equivalent to approx. 110 tonnes of CO2.

Utilization of surplus heat from the production process: We currently use a small proportion of this for heating in the storeroom in Building 1. In the long term, once the plant is fully up and running, the idea is to identify solutions to enable us to use surplus heat for heating of washing water.

Focus on optimising the work environment: Every quarter, the working environment team holds meetings with the plants in Assens, Poland and the US, where we discuss opportunities and new initiatives, and learn from one another’s experience.

Workplace assessment action plans (APV reports) are produced, and we follow up on all near-accidents and accidents.

|

Documentation requirements

Whole Building Life Cycle Assessment

A building LCA quantifies the lifetime, environmental impacts of the actions and processes needed to construct and operate a building in its lifetime (typically 50 years)

Product Life Cycle Assessment (LCA)

A product LCA quantifies the lifetime environmental impacts of the actions and processes needed to produce the product. The LCA is an internal company document, not suitable for external use.

Environmental Product Declaration (EPD)

An EPD quantifies the lifetime environmental impacts of a single product, based on the product LCA. It transparently reports objective, comparable and third-party verified data about the product’s environmental performances from a lifecycle perspective - in relation to building and construction. The EPD is made for external use towards the market.

|

The proof of success

Water consumption for production is generally covered by rainwater. We are able to store around 30,000 litres of water, and the amount of rainwater harvested and reused in our production has resulted in an annual saving of around 800,000 litres of drinking water.

A closed-loop system has been established with our brass supplier, who takes back all brass shavings for recycling. This means that on average our products contain approximately 70% recycled brass.Other waste fractions, such as various steel alloys, cardboard, paper, plastics, etc., are handled by a long-standing partner who arranges for their collection and treatment. Based on good source separation, a recycling rate of 98.2% has been achieved for these fractions in 2021. The remaining 1.8% of our waste is divided into 1.4% for incineration and 0.4% for landfill.

Comparison of the old BROEN BALLOMAX® DN50FP (weld x weld) and the new BROEN FULL FLOW DN50FP (weld x weld)

Did you know?“With the introduction of BROEN FULL FLOW valves, the weight of BROEN BALLOMAX® valves has decreased by more than 29.1% and flow performance has improved by 13%. This equates to 2.5 kCO2 per valve per year” |